The 20mm Measurement: A Quick Guide

In the world of precision engineering and manufacturing, measurements are a crucial aspect that can make or break a project. Among the myriad of measurement units and standards, the 20mm measurement holds significant importance in various industries, particularly in mechanical engineering, automotive, aerospace, and even in the production of everyday objects. This guide aims to provide an in-depth exploration of the 20mm measurement, its applications, and its impact on different sectors.

The Significance of 20mm

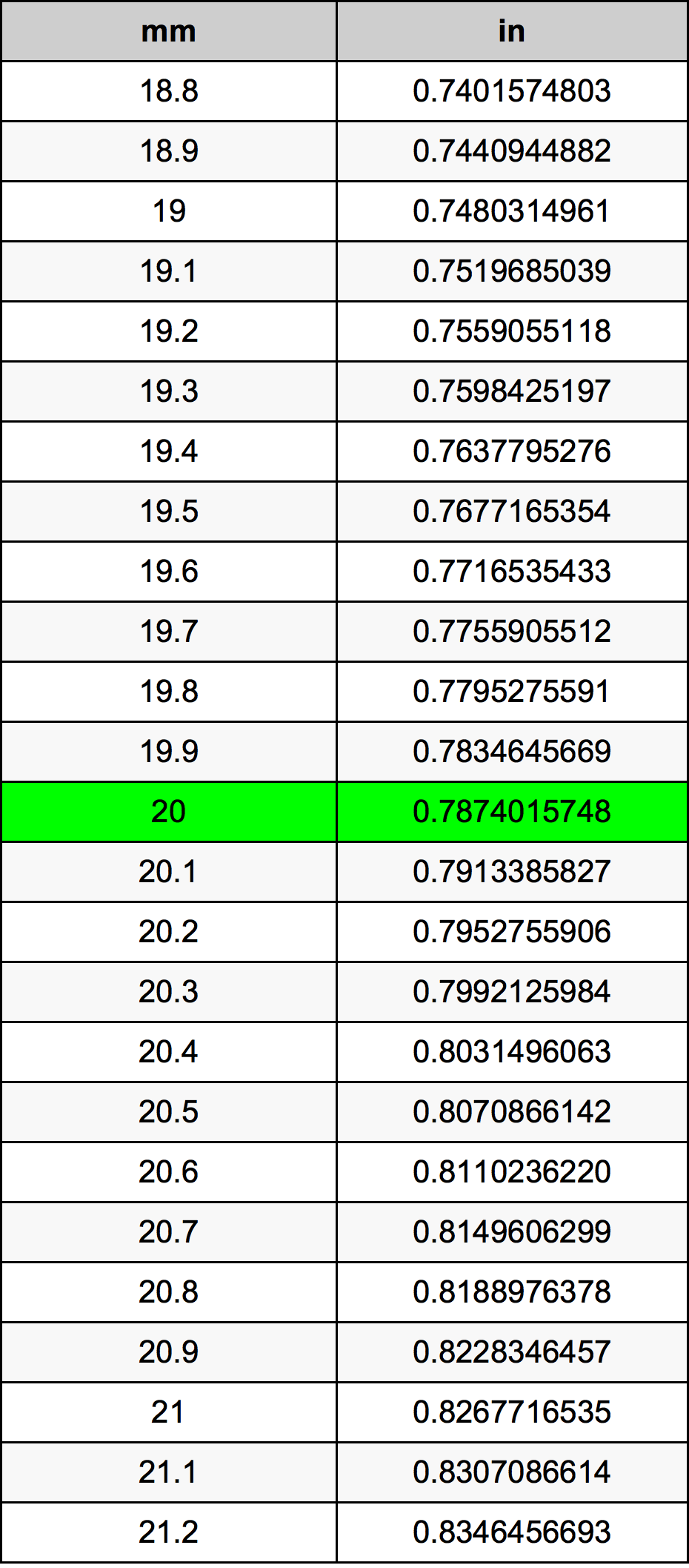

Measuring exactly 20 millimeters or 2 centimeters may seem like a straightforward task, but its implications extend far beyond simple arithmetic. This measurement unit plays a vital role in ensuring the proper functioning and safety of numerous products and systems. From the precise alignment of mechanical components to the spacing between electronic circuits, the accuracy of 20mm measurements can be a make-or-break factor in product quality and performance.

In the automotive industry, for instance, the 20mm measurement is frequently used to determine the spacing between various parts, such as the distance between a car's tires and its fenders, or the clearance between a vehicle's suspension components. Even a slight deviation from this measurement can lead to significant issues, affecting everything from ride quality to the vehicle's overall safety.

Applications Across Industries

The 20mm measurement finds application in a wide range of industries, each utilizing it for unique purposes.

Mechanical Engineering

In mechanical engineering, the 20mm measurement is crucial for determining the size and spacing of components in machines and devices. For example, in the design of a hydraulic press, the 20mm measurement might be used to specify the distance between the press’s ram and the base plate, ensuring optimal force application.

Similarly, in the production of gears, the 20mm measurement could define the spacing between gear teeth, ensuring smooth and efficient power transmission.

Automotive

As mentioned earlier, the automotive industry heavily relies on the 20mm measurement. From the design of engines to the spacing of electrical wiring, this measurement unit ensures the safe and efficient operation of vehicles. For instance, the 20mm measurement might be used to determine the distance between spark plugs and the cylinder head, optimizing combustion efficiency.

Aerospace

In the aerospace industry, precision is paramount. The 20mm measurement is used to ensure the accuracy of various components, from the spacing between an aircraft’s engine components to the dimensions of flight control surfaces. Even the smallest deviation from the 20mm measurement could lead to catastrophic failures, making this measurement unit a critical factor in aircraft safety.

Everyday Objects

The 20mm measurement isn’t limited to complex machinery or vehicles. It’s also used in the production of everyday objects, such as furniture, appliances, and even packaging. For instance, the 20mm measurement might be used to determine the spacing between the legs of a table, ensuring stability, or the diameter of a pipe fitting for a household plumbing system.

Precision Tools and Measurement Techniques

To ensure the accuracy of 20mm measurements, a variety of precision tools and measurement techniques are employed. These include:

- Digital Calipers: These electronic devices provide precise measurements down to fractions of a millimeter, making them ideal for measuring the 20mm distance accurately.

- Micrometers: Capable of measuring with extreme precision, micrometers are often used for critical measurements, such as the 20mm standard.

- Laser Interferometers: By using laser technology, these devices can measure distances with unparalleled accuracy, ensuring the 20mm measurement is met to the highest standards.

- Precision Rulers and Scales: While less precise than digital tools, these traditional measurement devices can still provide accurate 20mm measurements, especially when combined with careful calibration and use.

Impact on Quality and Performance

The accuracy of 20mm measurements has a direct impact on the quality and performance of products across various industries. Even the slightest deviation from this standard can lead to significant issues, including:

- Functional Failures: Inaccurate 20mm measurements can result in components not fitting together properly, leading to functional failures and potential safety hazards.

- Reduced Efficiency: Misaligned components or incorrect spacing can reduce the efficiency of machines, vehicles, and systems, leading to increased energy consumption and reduced productivity.

- Increased Wear and Tear: Improperly spaced components can cause excessive friction, leading to increased wear and tear, and reducing the lifespan of the product.

- Safety Risks: In critical industries like automotive and aerospace, inaccurate 20mm measurements can lead to serious safety risks, including potential mechanical failures and accidents.

The Future of 20mm Measurements

As technology continues to advance, the methods and tools used for 20mm measurements are likely to become even more precise and sophisticated. The development of new measurement technologies, such as advanced laser-based systems and even quantum-based metrology, could further revolutionize the accuracy and efficiency of these measurements.

Furthermore, the increasing focus on sustainability and resource efficiency in manufacturing means that accurate 20mm measurements will play an even more critical role in ensuring that products are designed and manufactured with minimal waste and maximum efficiency.

What are some common applications of the 20mm measurement in everyday life?

+The 20mm measurement is commonly used in the spacing of furniture legs, the diameter of pipe fittings, and even in the design of household appliances, ensuring everything from stability to efficient water flow.

How important is the accuracy of 20mm measurements in the automotive industry?

+In the automotive industry, accuracy in 20mm measurements is critical for ensuring the safe and efficient operation of vehicles. Even slight deviations can lead to reduced performance, increased wear and tear, and potential safety hazards.

What are some potential consequences of inaccurate 20mm measurements in aerospace applications?

+Inaccurate 20mm measurements in aerospace applications can lead to critical failures, including the malfunction of aircraft components, reduced flight performance, and potential safety risks for both the aircraft and its passengers.