Unveiling the Secrets of Process Analysis

Welcome to a comprehensive exploration of process analysis, a powerful tool for understanding and optimizing complex systems. In today's world, where efficiency and effectiveness are key to success, process analysis has become an indispensable technique across industries. From streamlining manufacturing processes to enhancing software development, this analytical approach has proven its worth time and again.

But what exactly is process analysis, and how can it benefit your organization? Let's delve into the intricacies of this methodology, uncovering its secrets and revealing its potential to transform your operations.

The Fundamentals of Process Analysis

At its core, process analysis is a systematic approach to understanding and improving processes. It involves breaking down a process into its constituent steps, examining each element, and identifying areas for enhancement. By analyzing inputs, outputs, and the sequence of activities, process analysis provides valuable insights that can lead to increased efficiency, reduced costs, and improved overall performance.

This analytical technique is particularly beneficial for complex processes that involve multiple steps, resources, and individuals. By visualizing and mapping out the process flow, analysts can identify bottlenecks, redundant steps, and areas where resources are being misallocated. With this information, organizations can make informed decisions to streamline their processes, enhance productivity, and deliver better outcomes.

Key Components of Process Analysis

Process Mapping

Process mapping is a critical first step in process analysis. It involves creating a visual representation of the process, often in the form of a flowchart or diagram. By mapping the process, analysts can gain a holistic understanding of the workflow, identify key stakeholders and their roles, and pinpoint areas where improvements can be made.

A well-designed process map should include all the necessary steps, decision points, and loops. It should also highlight any external factors or dependencies that influence the process. By visually representing the process, analysts can identify inefficiencies, such as redundant steps, delays, or unnecessary handoffs, which can then be addressed to optimize the process.

| Process Step | Description |

|---|---|

| Step 1: Initiation | Identify the trigger or input that starts the process. |

| Step 2: Activity Execution | Detail each activity, including resources, time, and outputs. |

| Step 3: Decision Points | Identify key decisions and their potential outcomes. |

| Step 4: Feedback Loops | Highlight any feedback mechanisms or loops for quality control. |

| Step 5: Termination | Define the end point of the process and its outcomes. |

Data Collection and Analysis

Process analysis relies on accurate data collection to inform decision-making. This involves gathering data on process inputs, outputs, and the resources utilized. By analyzing this data, analysts can identify trends, patterns, and areas where process improvements can be made.

For example, in a manufacturing process, data might include production times, resource usage, and quality control metrics. By analyzing this data, analysts can identify bottlenecks in the production line, areas where resources are being overutilized, or steps where quality control measures could be enhanced.

Advanced analytics techniques, such as statistical analysis and data visualization, can further enhance the insights gained from process analysis. These techniques can help identify complex relationships between process variables, allowing analysts to make more informed decisions and implement more effective process improvements.

Performance Metrics and Benchmarking

Establishing performance metrics is crucial for process analysis. These metrics should be aligned with the organization’s goals and objectives, providing a clear benchmark for evaluating process performance.

Performance metrics can include measures such as cycle time, productivity, error rates, or customer satisfaction. By tracking and analyzing these metrics over time, organizations can assess the impact of process improvements, identify areas where further enhancements are needed, and continuously strive for process excellence.

| Performance Metric | Description |

|---|---|

| Cycle Time | The time taken to complete a process from start to finish. |

| Productivity | A measure of the output produced per unit of input (e.g., time or resources) |

| Error Rate | The percentage of defects or errors in the process output. |

| Customer Satisfaction | A measure of customer perception and experience with the process. |

The Benefits of Process Analysis

Efficiency and Cost Reduction

One of the primary benefits of process analysis is its ability to identify and eliminate inefficiencies. By breaking down processes and analyzing each step, organizations can identify redundant or unnecessary activities, leading to streamlined workflows and reduced costs.

For instance, in a customer service process, process analysis might reveal that certain steps are adding unnecessary delays, causing customer frustration. By optimizing these steps, organizations can enhance customer satisfaction while reducing the time and resources required to resolve issues.

Improved Decision-Making

Process analysis provides a data-driven approach to decision-making. By analyzing process data and identifying trends, organizations can make informed choices about process improvements. This reduces the risk of implementing changes that may not have the desired impact, saving time and resources.

For example, in a software development process, process analysis might reveal that certain testing procedures are not effective in identifying bugs. By analyzing the data and making informed decisions, organizations can implement more efficient testing strategies, improving software quality and reducing development time.

Enhanced Quality and Customer Satisfaction

Process analysis can significantly enhance the quality of outputs and, consequently, customer satisfaction. By identifying and addressing issues such as errors, defects, or delays, organizations can deliver higher-quality products or services.

In a healthcare setting, process analysis might reveal that certain administrative processes are causing delays in patient care. By optimizing these processes, healthcare providers can improve patient outcomes, enhance the patient experience, and increase overall satisfaction.

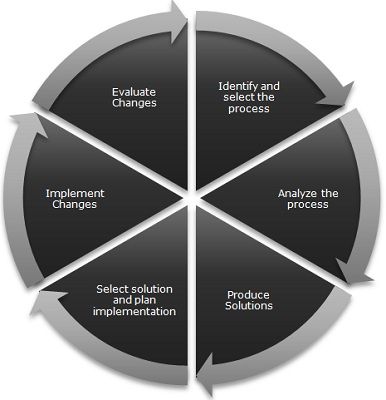

Continuous Improvement

Process analysis is not a one-time activity; it is an ongoing process. By regularly analyzing processes and implementing improvements, organizations can achieve continuous improvement, staying ahead of the competition and adapting to changing market dynamics.

Through process analysis, organizations can identify new opportunities for innovation, streamline existing processes, and enhance their overall operational excellence. This continuous improvement mindset ensures that organizations remain agile and responsive, delivering the best possible outcomes for their customers and stakeholders.

Best Practices for Process Analysis

Engage Stakeholders

Process analysis is most effective when it involves all relevant stakeholders. By engaging those directly involved in the process, analysts can gain valuable insights and perspectives, ensuring that the analysis is comprehensive and accurate.

Additionally, involving stakeholders in the process analysis and improvement process fosters a sense of ownership and commitment. This can lead to greater acceptance and implementation of process improvements, as stakeholders feel invested in the outcome.

Use Appropriate Tools and Techniques

There are numerous tools and techniques available for process analysis, including process mapping software, data analytics platforms, and quality management tools. Choosing the right tools for the specific process and organization is crucial for effective analysis.

For example, a manufacturing organization might benefit from using a process mapping tool that integrates with their existing ERP system, providing a seamless flow of data for analysis. On the other hand, a service-based organization might find value in a cloud-based process mapping tool that allows for real-time collaboration and feedback.

Establish Clear Objectives

Before initiating process analysis, it is essential to establish clear objectives. These objectives should align with the organization’s goals and priorities, ensuring that the analysis focuses on the most critical aspects of the process.

Clear objectives provide a framework for the analysis, guiding the collection and analysis of data. They also help in prioritizing process improvements, ensuring that the most impactful changes are implemented first.

Consider Cultural and Organizational Factors

Process analysis should consider the cultural and organizational context in which the process operates. Cultural factors, such as communication styles or attitudes towards change, can significantly impact the success of process improvements.

For instance, in a highly hierarchical organization, implementing process improvements might require additional steps to gain buy-in from senior leadership. Understanding and addressing these cultural factors is crucial for the successful implementation of process changes.

Future Trends in Process Analysis

Artificial Intelligence and Machine Learning

The integration of artificial intelligence (AI) and machine learning (ML) is set to revolutionize process analysis. These technologies can automate data collection, analysis, and process mapping, providing faster and more accurate insights.

AI and ML algorithms can identify patterns and relationships in process data that might not be apparent to human analysts. This can lead to more efficient process improvements and the identification of new opportunities for innovation.

Process Mining and Process Discovery

Process mining and process discovery techniques are gaining traction in process analysis. These techniques involve analyzing event logs and other process data to uncover hidden process patterns and variations.

By using process mining, organizations can identify process deviations and bottlenecks that might not be apparent through traditional process mapping. This can lead to more targeted process improvements and a deeper understanding of process dynamics.

Collaborative Process Analysis

The future of process analysis lies in collaboration. By leveraging cloud-based platforms and real-time collaboration tools, process analysis can become a truly collaborative effort, involving stakeholders from different departments and even external partners.

Collaborative process analysis can lead to more innovative solutions, as diverse perspectives are brought to bear on process challenges. It also fosters a culture of continuous improvement, as stakeholders from across the organization are engaged in process analysis and optimization.

What are the key steps in process analysis?

+

Process analysis typically involves several steps: process mapping, data collection and analysis, performance metric establishment, and process improvement implementation. These steps ensure a comprehensive understanding of the process and allow for informed decision-making and continuous improvement.

How can process analysis benefit my organization?

+

Process analysis can lead to increased efficiency, reduced costs, improved quality, and enhanced customer satisfaction. By identifying and addressing process inefficiencies, organizations can optimize their operations, deliver better outcomes, and stay competitive in the market.

What tools are commonly used in process analysis?

+

Process analysis tools include process mapping software, data analytics platforms, quality management tools, and, increasingly, artificial intelligence and machine learning technologies. The choice of tools depends on the specific process and organizational needs.

How often should process analysis be conducted?

+

Process analysis should be conducted on a regular basis as part of an organization’s continuous improvement efforts. The frequency of analysis may vary depending on the nature of the process and the rate of change in the organization’s environment. It’s important to stay agile and responsive to changing dynamics.

What challenges might I face in process analysis?

+

Challenges in process analysis may include resistance to change, data collection and analysis complexities, and cultural or organizational barriers. Overcoming these challenges requires stakeholder engagement, clear objectives, and a deep understanding of the process context.