The Ultimate Guide: 5 Maintenance Tips

Welcome to the ultimate guide on maintenance, a crucial aspect of ensuring the longevity and optimal performance of various systems, machinery, and infrastructure. In this comprehensive article, we will delve into the world of maintenance practices, uncovering five essential tips that will revolutionize the way you approach maintenance tasks. Whether you're a business owner, facility manager, or simply an individual looking to maintain your valuable assets, these insights will provide you with the knowledge and strategies to excel in the field of maintenance.

Maximizing Efficiency: The Art of Effective Maintenance

Maintenance is not merely a routine task; it is an art that, when mastered, can significantly enhance the efficiency and reliability of your operations. By implementing strategic maintenance practices, you can minimize downtime, reduce costs, and prolong the lifespan of your equipment. This guide aims to empower you with the expertise needed to navigate the intricate world of maintenance, ensuring that your systems remain in peak condition.

Tip 1: Embrace Preventive Maintenance Strategies

The cornerstone of effective maintenance lies in adopting a proactive approach. Preventive maintenance is a powerful tool that allows you to anticipate and address potential issues before they escalate into costly breakdowns. By regularly scheduling maintenance activities, you can identify and rectify minor problems, ensuring that your equipment operates smoothly and reliably.

One of the key advantages of preventive maintenance is its ability to reduce unexpected failures. Through routine inspections, lubrication, and component replacements, you can catch early signs of wear and tear, preventing major malfunctions that may lead to expensive repairs or even equipment replacement.

Implementing a well-structured preventive maintenance program involves creating a comprehensive schedule that outlines the frequency and scope of maintenance tasks. This schedule should consider the specific needs of each piece of equipment, taking into account factors such as usage, age, and manufacturer recommendations.

Additionally, utilizing condition monitoring techniques can further enhance your preventive maintenance strategy. By employing sensors and advanced analytics, you can continuously monitor the health of your equipment, detecting subtle changes in performance that may indicate an impending issue. This real-time data enables you to make informed decisions and take proactive measures to mitigate potential failures.

Benefits of Preventive Maintenance

- Reduced equipment downtime and increased operational efficiency.

- Lower maintenance costs by preventing costly repairs and replacements.

- Improved equipment lifespan and reliability.

- Enhanced safety by identifying and rectifying potential hazards early on.

Real-World Example

Imagine a manufacturing facility that relies on a complex network of machinery to produce its products. By implementing a robust preventive maintenance program, the facility can ensure that each machine receives regular attention. This includes routine inspections, oil changes, and the replacement of worn-out parts. Through this proactive approach, the facility has experienced a significant reduction in unexpected breakdowns, leading to improved productivity and a more efficient workflow.

Tip 2: Optimize Your Maintenance Schedule with Predictive Analytics

While preventive maintenance is a powerful tool, it is not a one-size-fits-all solution. Different equipment and systems have unique maintenance requirements, and understanding these nuances is essential for maximizing efficiency. This is where predictive analytics comes into play, offering a data-driven approach to maintenance scheduling.

Predictive analytics utilizes advanced algorithms and machine learning techniques to analyze historical maintenance data, equipment performance metrics, and external factors such as weather conditions. By leveraging this data, you can make informed decisions about when and how to perform maintenance tasks, optimizing the frequency and timing of interventions.

By implementing predictive analytics, you can achieve several key benefits:

- Improved Maintenance Efficiency: Predictive analytics allows you to prioritize maintenance tasks based on the criticality and urgency of each piece of equipment. This ensures that your maintenance resources are allocated effectively, focusing on the most crucial tasks first.

- Reduced Unplanned Downtime: By predicting potential failures and scheduling maintenance activities accordingly, you can minimize the occurrence of unexpected breakdowns. This proactive approach helps keep your operations running smoothly and reduces the impact of downtime on productivity.

- Enhanced Equipment Performance: Through predictive analytics, you can identify patterns and trends in equipment behavior, allowing you to make data-driven decisions about equipment upgrades, replacements, or adjustments. This proactive management of equipment performance can lead to significant improvements in overall efficiency.

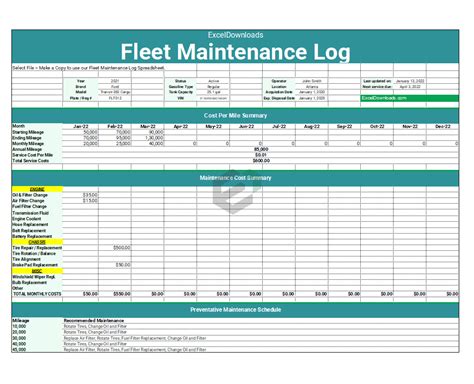

To illustrate the power of predictive analytics, consider a scenario where a manufacturing plant utilizes this technology to monitor its fleet of vehicles. By analyzing historical data and real-time sensor readings, the plant can predict when each vehicle is likely to require maintenance. This allows the plant to schedule maintenance activities during off-peak hours, minimizing the impact on production and ensuring that vehicles remain in optimal condition.

Tip 3: Leverage Technology for Efficient Maintenance

In today’s digital age, technology offers a wealth of opportunities to streamline and enhance maintenance practices. From maintenance management software to advanced sensors and automation, leveraging technology can revolutionize the way you approach maintenance tasks.

One of the key advantages of technology-driven maintenance is the ability to centralize maintenance data. By utilizing maintenance management software, you can create a digital repository of maintenance records, work orders, and equipment specifications. This centralized system provides a comprehensive overview of your maintenance activities, enabling you to track progress, analyze trends, and make informed decisions.

Furthermore, technology enables the implementation of automated maintenance processes. Through the use of sensors and real-time monitoring systems, you can receive instant notifications when equipment requires attention. This automation not only reduces the reliance on manual inspections but also ensures that maintenance tasks are triggered promptly, minimizing the risk of equipment failures.

Additionally, technology facilitates remote monitoring and diagnostics, allowing maintenance personnel to access equipment data and performance metrics from anywhere. This remote access capability is particularly valuable for organizations with multiple sites or remote locations, as it enables efficient maintenance coordination and troubleshooting without the need for physical presence.

By embracing technology in your maintenance practices, you can achieve a higher level of efficiency, accuracy, and responsiveness. This not only improves the overall maintenance experience but also contributes to a more sustainable and cost-effective operation.

Benefits of Technology-Driven Maintenance

- Improved data accuracy and real-time insights through centralized maintenance records.

- Enhanced productivity and reduced downtime through automated maintenance processes.

- Remote monitoring and diagnostics capabilities for efficient troubleshooting.

- Cost savings through optimized resource allocation and reduced equipment failures.

Real-World Example

A hospital facility has implemented a technology-driven maintenance system, utilizing sensors and automated maintenance processes. Through this system, the facility can monitor the performance of its critical medical equipment in real-time. When an issue is detected, the system automatically generates a work order and notifies the maintenance team. This efficient process ensures that equipment issues are addressed promptly, minimizing disruptions to patient care and maximizing the availability of medical resources.

Tip 4: Foster a Culture of Maintenance Awareness

While technology and strategic maintenance practices are crucial, the success of your maintenance program also relies on the engagement and awareness of your workforce. Fostering a culture of maintenance awareness is essential to ensure that everyone understands the importance of maintenance and actively contributes to its success.

To cultivate a culture of maintenance awareness, consider the following strategies:

- Education and Training: Provide comprehensive training programs for your employees, covering the basics of maintenance, its importance, and the impact of proper maintenance practices on overall operational efficiency. Ensure that all staff members, from operators to managers, understand their role in maintaining equipment and systems.

- Incentivize Maintenance Best Practices: Implement recognition programs or reward systems that encourage employees to actively participate in maintenance activities. Recognizing and rewarding employees who demonstrate exceptional maintenance practices can motivate others to follow suit and create a positive maintenance culture.

- Open Communication Channels: Establish clear communication channels where employees can report equipment issues, suggest improvements, or provide feedback on maintenance practices. Encourage an open and collaborative environment where maintenance concerns are addressed promptly and seriously.

- Lead by Example: Demonstrate your commitment to maintenance by actively participating in maintenance activities and setting a positive example for your team. Your involvement sends a powerful message that maintenance is a priority and a shared responsibility.

By fostering a culture of maintenance awareness, you create an environment where employees feel empowered to take ownership of maintenance tasks and contribute to the overall success of the organization. This collaborative approach not only improves maintenance outcomes but also enhances employee engagement and satisfaction.

Benefits of a Maintenance-Aware Culture

- Increased employee engagement and buy-in for maintenance practices.

- Improved equipment uptime and reduced downtime through proactive reporting.

- Enhanced safety culture as employees become more aware of potential hazards.

- Improved overall operational efficiency and productivity.

Real-World Example

A manufacturing company has successfully fostered a culture of maintenance awareness by implementing regular maintenance training sessions for all employees. These sessions cover topics such as equipment safety, proper maintenance procedures, and the importance of timely maintenance. As a result, employees feel empowered to report equipment issues promptly, leading to faster resolution times and reduced downtime. This collaborative approach has not only improved maintenance outcomes but has also boosted employee morale and overall job satisfaction.

Tip 5: Continuously Evaluate and Improve Your Maintenance Program

Maintenance is an ongoing process, and to ensure its effectiveness, it is crucial to continuously evaluate and improve your maintenance program. Regularly assessing your maintenance practices allows you to identify areas for enhancement, adapt to changing needs, and stay ahead of potential challenges.

To effectively evaluate and improve your maintenance program, consider the following steps:

- Data Analysis: Utilize maintenance management software or other data collection tools to gather and analyze maintenance-related data. This includes equipment performance metrics, maintenance records, and cost data. By analyzing this data, you can identify trends, pinpoint areas of improvement, and make data-driven decisions to optimize your maintenance program.

- Performance Benchmarking: Compare your maintenance program’s performance against industry benchmarks or best practices. This allows you to identify gaps and set realistic goals for improvement. Benchmarking can help you stay ahead of the competition and continuously enhance your maintenance practices.

- Employee Feedback: Encourage open communication and solicit feedback from your maintenance team and other employees. Their insights and experiences can provide valuable perspectives on the effectiveness of your maintenance program and areas where improvements can be made. Actively listen to their suggestions and implement changes accordingly.

- Regular Reviews and Updates: Schedule periodic reviews of your maintenance program to assess its overall effectiveness. These reviews should involve key stakeholders, including maintenance managers, operations managers, and executive leadership. By regularly evaluating and updating your maintenance program, you can ensure that it remains aligned with your organization’s goals and evolving needs.

By continuously evaluating and improving your maintenance program, you demonstrate a commitment to excellence and ensure that your maintenance practices remain cutting-edge. This proactive approach not only enhances equipment reliability and operational efficiency but also contributes to a more sustainable and cost-effective operation.

Benefits of Continuous Improvement

- Enhanced equipment reliability and reduced downtime through proactive maintenance.

- Improved maintenance program effectiveness and alignment with organizational goals.

- Increased cost savings through optimized maintenance practices and reduced equipment failures.

- Continuous learning and adaptation to stay ahead of industry trends and best practices.

Real-World Example

A data center facility has implemented a comprehensive maintenance program evaluation process. Through regular data analysis, they identified that a specific type of server was experiencing frequent failures. By benchmarking their maintenance practices against industry standards, they discovered that their maintenance schedule for this server type was not optimal. As a result, they adjusted their maintenance program, implementing more frequent inspections and proactive maintenance tasks. This continuous improvement process led to a significant reduction in server failures and improved overall data center reliability.

Conclusion

In conclusion, effective maintenance is a cornerstone of successful operations, and by implementing the five tips outlined in this guide, you can revolutionize your maintenance practices. From embracing preventive maintenance to optimizing your schedule with predictive analytics, leveraging technology, fostering a culture of awareness, and continuously evaluating your program, you’ll be well-equipped to navigate the intricacies of maintenance with confidence and expertise.

FAQ

How often should I perform preventive maintenance tasks?

+

The frequency of preventive maintenance tasks depends on several factors, including the type of equipment, its usage, and manufacturer recommendations. It is essential to create a comprehensive maintenance schedule that considers these factors and ensures regular attention to all critical equipment.

What are some common signs that equipment may require maintenance?

+

Common signs that equipment may require maintenance include unusual noises, vibrations, reduced performance, leaks, or error codes. Regular inspections and condition monitoring can help identify these signs early on, allowing for timely maintenance interventions.

How can I implement predictive analytics in my maintenance program?

+

To implement predictive analytics, you can utilize advanced maintenance management software that incorporates machine learning algorithms. These tools analyze historical data and equipment performance metrics to predict potential failures and optimize maintenance schedules.