The Weight of Cylinders: Unveiled

Welcome to an in-depth exploration of the weight of cylinders, a topic that is integral to various industries and applications. The weight of a cylinder, a seemingly simple concept, plays a crucial role in engineering, transportation, and even everyday life. In this article, we will delve into the intricacies of cylinder weight, its measurement, and its significance in different contexts. Get ready to uncover the secrets behind this often-overlooked aspect of cylindrical objects.

The Science Behind Cylinder Weight

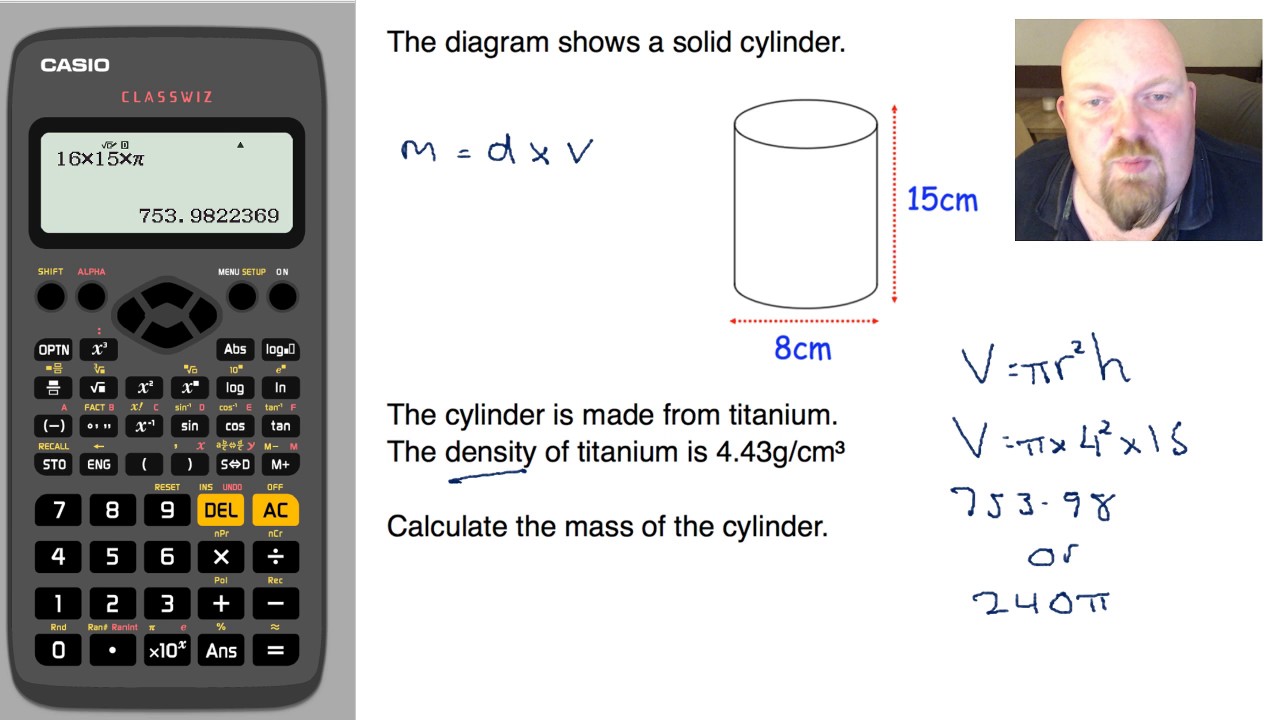

Cylinder weight is more than just a measure of mass; it is a complex interplay of several factors. The weight of a cylinder is determined by its material composition, dimensions, and even the specific gravity of the fluid it contains. Understanding these factors is key to accurately predicting and managing cylinder weight.

Material Composition and Its Impact

The choice of material for a cylinder has a profound effect on its weight. Different materials have varying densities, which directly influence the overall weight of the cylinder. For instance, a stainless steel cylinder will typically be heavier than an aluminum one of the same dimensions. The material’s strength and corrosion resistance also play a role, as they determine the cylinder’s durability and suitability for specific applications.

| Material | Density (kg/m3) |

|---|---|

| Aluminum | 2700 |

| Stainless Steel | 7900 |

| Titanium | 4500 |

Dimensions: Size Matters

The dimensions of a cylinder, including its length, diameter, and wall thickness, significantly impact its weight. A longer cylinder will generally weigh more than a shorter one, all else being equal. Similarly, a cylinder with a larger diameter or thicker walls will have a higher weight. The relationship between dimensions and weight is governed by the cylinder’s volume and the density of its material.

| Cylinder | Length (m) | Diameter (m) | Wall Thickness (mm) | Weight (kg) |

|---|---|---|---|---|

| A | 1 | 0.1 | 2 | 2.7 |

| B | 1.5 | 0.15 | 3 | 5.5 |

| C | 2 | 0.2 | 4 | 11 |

The Role of Specific Gravity

Specific gravity, the ratio of the density of a substance to the density of a reference substance (usually water), is another critical factor. When a cylinder contains a fluid, the specific gravity of that fluid influences its overall weight. For instance, a cylinder filled with mercury will be significantly heavier than one filled with water, despite having the same dimensions.

| Fluid | Specific Gravity |

|---|---|

| Water | 1 |

| Mercury | 13.5 |

| Ethanol | 0.79 |

Practical Applications and Challenges

The weight of cylinders becomes particularly relevant in practical applications, where it can impact performance, safety, and cost. Whether it’s in industrial settings, transportation, or everyday consumer products, understanding and managing cylinder weight is crucial.

Industrial and Engineering Considerations

In industrial and engineering contexts, cylinder weight is a critical factor in the design and operation of various systems. For example, in gas cylinder manufacturing for industrial use, the weight of the cylinder must be optimized to ensure it can safely contain and transport gases while also being easy to handle and transport.

Consider a case study where a manufacturing plant requires high-pressure gas cylinders for a new production line. The plant manager must select cylinders that can withstand the pressure while also being lightweight enough for easy handling. This requires a careful balance between material choice, dimensions, and weight.

Transportation and Mobility

The weight of cylinders is a key consideration in transportation and mobility applications. In the automotive industry, for instance, the weight of cylinders in engines directly affects fuel efficiency and performance. Lighter cylinders can lead to improved fuel economy and reduced emissions, making weight optimization a critical aspect of engine design.

Similarly, in the aerospace industry, the weight of cylinders used for storing gases or fluids is crucial. Every kilogram saved in the weight of these cylinders can significantly reduce the overall weight of the aircraft, leading to improved fuel efficiency and range.

Challenges and Innovations

While the weight of cylinders is a well-understood concept, it presents several challenges, especially in applications where weight reduction is critical. Innovative solutions, such as advanced materials and manufacturing techniques, are constantly being developed to address these challenges.

One such innovation is the use of composite materials in cylinder construction. Composite cylinders, often made of fiber-reinforced polymers, can offer significant weight savings compared to traditional metal cylinders. These composites provide high strength-to-weight ratios, making them ideal for applications where weight is a primary concern.

Future Trends and Innovations

As technology advances and new materials and manufacturing processes emerge, the future of cylinder weight looks promising. Several trends and innovations are shaping the way cylinders are designed and manufactured, with a focus on weight reduction and improved performance.

Additive Manufacturing

Additive manufacturing, or 3D printing, is revolutionizing the way cylinders are produced. This technology allows for the creation of complex, lightweight cylinder designs that were previously impossible or cost-prohibitive. By building cylinders layer by layer, additive manufacturing can create hollow structures with thin walls, reducing weight while maintaining structural integrity.

Smart Materials and Sensors

The integration of smart materials and sensors into cylinders is another emerging trend. These technologies can provide real-time data on the weight and structural integrity of cylinders, allowing for predictive maintenance and ensuring safe operation. For example, sensors embedded in a cylinder can monitor its weight distribution and alert operators if it exceeds safe limits.

Sustainable and Eco-Friendly Solutions

With a growing focus on sustainability, the future of cylinder weight also involves the development of eco-friendly solutions. This includes the use of recycled materials in cylinder construction and the design of cylinders with end-of-life recycling in mind. By reducing the environmental impact of cylinders, these sustainable solutions can contribute to a greener future.

Conclusion: A Weighty Matter

The weight of cylinders, though often overlooked, is a critical aspect of many industries and applications. From industrial manufacturing to transportation and everyday consumer products, understanding and managing cylinder weight is essential for optimizing performance, safety, and cost. As technology advances and new innovations emerge, the future of cylinder weight management looks promising, offering lightweight, sustainable, and smart solutions.

How is the weight of a cylinder calculated?

+The weight of a cylinder is calculated using its volume, the density of its material, and the specific gravity of any fluid it contains. The formula is: Weight = Volume x Density x Specific Gravity.

Why is cylinder weight important in industrial applications?

+In industrial applications, cylinder weight is critical for ensuring safe handling and transportation. It also impacts the overall efficiency and cost-effectiveness of the industrial process, as heavier cylinders can lead to increased transportation and handling costs.

What are some innovative materials used to reduce cylinder weight?

+Innovative materials such as fiber-reinforced polymers and composite materials are being used to reduce cylinder weight while maintaining strength. These materials offer high strength-to-weight ratios and are increasingly being adopted in various industries.