Log Board Footage Calculator Made Easy

In the realm of woodworking and construction, understanding and calculating log board footage is an essential skill. This process, often complex and intricate, plays a crucial role in determining the volume and value of timber. Accurate calculations ensure that woodworkers, carpenters, and timber merchants can make informed decisions regarding material procurement, pricing, and project planning. This article aims to demystify the art of log board footage calculation, offering a comprehensive guide to simplify this vital task.

The Fundamentals of Log Board Footage

Log board footage refers to the measurement of timber, typically in terms of board feet. A board foot is a unit of volume equal to a board 1 foot long, 1 foot wide, and 1 inch thick. However, calculating log board footage involves more than a simple multiplication of these dimensions. It necessitates an understanding of the unique characteristics of logs and their transformation into boards.

When a log is converted into boards, several factors come into play. The log's diameter, length, and the desired thickness of the boards all influence the final board footage. Additionally, the presence of defects, such as knots or splits, can impact the usable volume of timber. These variables make the calculation of log board footage a challenging but crucial task.

Key Concepts in Log Board Footage Calculation

To accurately determine log board footage, several concepts must be understood. Firstly, the log scale refers to the method used to estimate the volume of a log. This is often done by measuring the log’s diameter and length and applying a formula specific to the log’s species and intended use. The resulting volume is then adjusted for defects and shrinkage to provide an accurate representation of the log’s usable timber.

Secondly, the board scale comes into play when converting the log's volume into board feet. This process involves determining the number of boards that can be obtained from the log, considering the desired board thickness and the log's characteristics. The board scale takes into account factors such as the log's taper, the desired width of the boards, and the presence of defects, ensuring an accurate calculation of the board footage.

| Log Diameter (inches) | Board Feet |

|---|---|

| 12 | 20.5 |

| 14 | 27.2 |

| 16 | 34.7 |

| 18 | 43.0 |

| 20 | 52.3 |

Step-by-Step Guide to Calculating Log Board Footage

Calculating log board footage requires a systematic approach. Here’s a detailed breakdown of the process:

Step 1: Measuring the Log

The first step is to accurately measure the log. This involves determining the log’s length and average diameter. The length is typically measured from end to end, while the diameter is measured at multiple points along the log’s length, with the average value used for the calculation. It’s crucial to ensure that the measurements are taken at the correct points to avoid inaccuracies.

Step 2: Choosing the Appropriate Log Scale

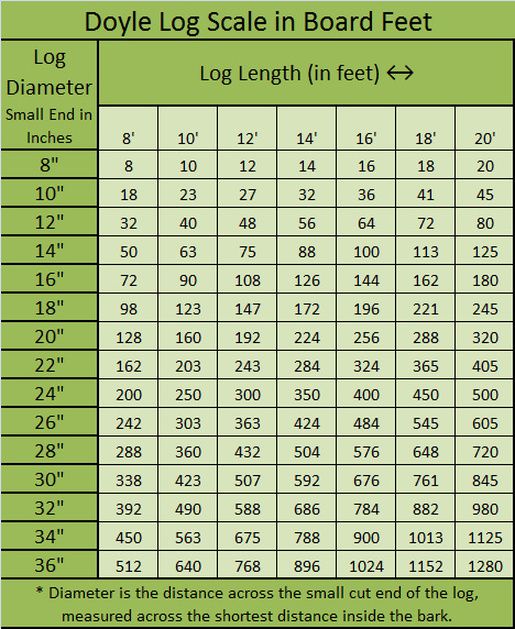

Different log scales are used for different species of wood and intended uses. For example, the Doyle scale is commonly used for softwoods, while the Scribner scale is often applied to hardwoods. The choice of scale depends on the characteristics of the log and the desired accuracy of the calculation. It’s essential to consult a reference guide or seek expert advice to select the correct scale.

Step 3: Applying the Log Scale Formula

Once the log scale is chosen, the appropriate formula is applied to calculate the log’s volume. The formula varies based on the scale, but typically involves multiplying the log’s length by its average diameter and applying a scaling factor. This scaling factor accounts for the log’s taper and other characteristics, ensuring an accurate volume calculation.

Step 4: Adjusting for Defects and Shrinkage

Logs often contain defects, such as knots, cracks, or splits, which reduce the usable volume of timber. These defects must be accounted for in the calculation. Additionally, logs can shrink as they dry, leading to further volume reduction. To address these factors, a defect and shrinkage factor is applied to the calculated volume, providing a more accurate representation of the log’s usable timber.

Step 5: Determining Board Thickness and Width

The desired thickness and width of the boards to be obtained from the log are critical factors in the calculation. Thicker boards will result in fewer board feet, while wider boards may increase the overall volume. It’s essential to consider the intended use of the boards and the market demand when determining these dimensions.

Step 6: Applying the Board Scale

With the log’s volume adjusted for defects and shrinkage, and the desired board dimensions determined, the board scale can be applied. This involves calculating the number of boards that can be obtained from the log, considering its volume and the desired board dimensions. The board scale formula varies based on the scale chosen and the specific characteristics of the log.

Step 7: Calculating Board Feet

Finally, the calculated number of boards is converted into board feet. This involves multiplying the number of boards by the desired board thickness and width, then dividing by the standard board foot volume (144 cubic inches). This step provides the final log board footage, representing the usable volume of timber from the log.

Practical Examples and Case Studies

To illustrate the process of calculating log board footage, let’s explore a few practical examples. These case studies will demonstrate the application of the steps outlined above, providing a clearer understanding of the calculation process.

Example 1: Softwood Log for Construction

Imagine a softwood log, with a length of 16 feet and an average diameter of 12 inches. Using the Doyle scale, the log’s volume is calculated as follows:

Volume = Length x Average Diameter x Scaling Factor

Volume = 16 ft x 12 in x 0.72 (Doyle scaling factor)

Volume = 138.24 cubic feet

After adjusting for defects and shrinkage, the usable volume is determined to be 120 cubic feet. With a desired board thickness of 1 inch and a width of 6 inches, the number of boards can be calculated as follows:

Number of Boards = Usable Volume / (Board Thickness x Board Width)

Number of Boards = 120 cubic feet / (1 in x 6 in)

Number of Boards = 200 boards

Finally, the board feet are calculated:

Board Feet = Number of Boards x Board Thickness x Board Width / 144

Board Feet = 200 boards x 1 in x 6 in / 144

Board Feet = 83.33 board feet

Example 2: Hardwood Log for Furniture Making

Consider a hardwood log, with a length of 12 feet and an average diameter of 14 inches. Using the Scribner scale, the log’s volume is calculated as follows:

Volume = Length x Average Diameter x Scaling Factor

Volume = 12 ft x 14 in x 0.80 (Scribner scaling factor)

Volume = 134.4 cubic feet

After adjustments for defects and shrinkage, the usable volume is 110 cubic feet. With a desired board thickness of 0.75 inches and a width of 8 inches, the number of boards is calculated as follows:

Number of Boards = Usable Volume / (Board Thickness x Board Width)

Number of Boards = 110 cubic feet / (0.75 in x 8 in)

Number of Boards = 173.33 boards

The board feet are then calculated:

Board Feet = Number of Boards x Board Thickness x Board Width / 144

Board Feet = 173.33 boards x 0.75 in x 8 in / 144

Board Feet = 79.86 board feet

Advanced Techniques and Considerations

While the basic steps outlined above provide a solid foundation for calculating log board footage, there are advanced techniques and considerations to enhance the accuracy and efficiency of the process.

Utilizing Software and Apps

In today’s digital age, various software and apps are available to assist in log board footage calculations. These tools often provide user-friendly interfaces, allowing woodworkers and timber professionals to input log measurements and instantly obtain calculated board footage. While these tools can streamline the process, it’s essential to understand the underlying principles to ensure accurate results.

Accounting for Species-Specific Characteristics

Different species of wood have unique characteristics that can impact log board footage calculations. For example, some species are more prone to defects or shrinkage, while others may have distinct growth patterns that influence the log’s volume. It’s crucial to consider these species-specific factors when choosing the appropriate log scale and applying adjustments for defects and shrinkage.

Optimizing Board Yield

Maximizing the board yield from a log is a critical consideration in log board footage calculations. This involves determining the optimal board thickness and width to minimize waste and maximize the usable volume of timber. By carefully considering the intended use of the boards and market demand, woodworkers and timber professionals can make informed decisions to optimize board yield and overall profitability.

Managing Moisture Content

Moisture content plays a significant role in log board footage calculations. As logs dry, they can shrink, impacting the final board footage. Managing moisture content involves understanding the drying process and applying appropriate adjustments to the calculations. This ensures that the calculated board footage accurately represents the usable volume of timber, even as the log undergoes changes in moisture content.

Conclusion: Mastering Log Board Footage Calculations

Calculating log board footage is a complex but essential skill for woodworkers, carpenters, and timber professionals. By understanding the fundamentals, following a systematic approach, and considering advanced techniques, accurate calculations can be achieved. This, in turn, enables informed decision-making, optimal material utilization, and precise pricing strategies.

As the demand for sustainable and high-quality timber products continues to grow, the ability to accurately calculate log board footage becomes increasingly vital. By mastering this skill, woodworkers and timber professionals can contribute to the efficient and responsible use of this precious natural resource, ensuring its availability for future generations.

How do I choose the right log scale for my calculation?

+The choice of log scale depends on the species of wood and the intended use. Softwoods typically use scales like Doyle or Scribner, while hardwoods often employ scales like International or Scribner. It’s essential to consult a reference guide or seek expert advice to select the appropriate scale for your specific log.

Can I use an app or software to calculate log board footage accurately?

+Yes, various apps and software tools are available to assist with log board footage calculations. However, it’s crucial to ensure that the app or software you choose is reliable and accounts for all the necessary factors, such as species-specific characteristics, defects, and moisture content. Always double-check the calculations and understand the underlying principles to ensure accuracy.

How do defects and shrinkage impact the final board footage calculation?

+Defects, such as knots or cracks, and shrinkage due to drying can significantly reduce the usable volume of timber. These factors must be accounted for in the log volume calculation and the board yield determination. Adjustments for defects and shrinkage ensure that the final board footage calculation accurately represents the amount of usable timber from the log.