The Ultimate Guide to 10-Hour Shift Scheduling

In the world of manufacturing and logistics, 10-hour shift scheduling is a common practice to optimize operations and maintain productivity. It offers a unique balance between extended work periods and adequate recovery time. This comprehensive guide will delve into the intricacies of 10-hour shift scheduling, exploring its benefits, potential challenges, and effective strategies for implementation.

Maximizing Productivity with 10-Hour Shifts

The concept of 10-hour shift scheduling has gained traction in various industries due to its ability to enhance productivity while providing a reasonable work-life balance. By extending work hours to 10 hours a day, organizations can achieve significant advantages.

One of the primary benefits is increased output. A 10-hour shift allows for more productive work time compared to traditional 8-hour shifts. This extended period enables employees to complete more tasks, leading to higher productivity and improved operational efficiency.

Productivity Metrics

Let’s consider a manufacturing plant that implements 10-hour shifts. Data analysis reveals a 25% increase in production output compared to the previous 8-hour shift schedule. This significant boost in productivity is a direct result of the extended work hours, allowing employees to maximize their time on the job.

| Shift Type | Productivity Index |

|---|---|

| 8-Hour Shift | 100 |

| 10-Hour Shift | 125 |

The table above showcases the productivity difference between the two shift types. With a 25-point increase in the productivity index, the 10-hour shift schedule proves its effectiveness in maximizing output.

Enhanced Efficiency

Another advantage of 10-hour shifts is improved efficiency. By having a longer uninterrupted work period, employees can focus on their tasks without frequent breaks. This uninterrupted workflow enhances concentration and minimizes downtime, resulting in more efficient operations.

Additionally, 10-hour shifts can reduce the number of shift changes, which often disrupt workflow and require additional coordination. Fewer shift changes mean less downtime and a smoother operational flow.

Challenges and Considerations

While 10-hour shift scheduling offers numerous benefits, it also presents certain challenges that organizations must address for a successful implementation.

Employee Well-Being and Fatigue Management

One of the primary concerns with extended work hours is employee fatigue. Working 10-hour shifts can be physically and mentally demanding, especially if employees are not accustomed to such schedules. It is crucial to prioritize employee well-being and implement fatigue management strategies.

Organizations should ensure that employees have adequate rest and recovery time between shifts. Scheduling regular breaks and providing ergonomic workstations can help mitigate fatigue and maintain employee health and safety.

Shift Scheduling Complexity

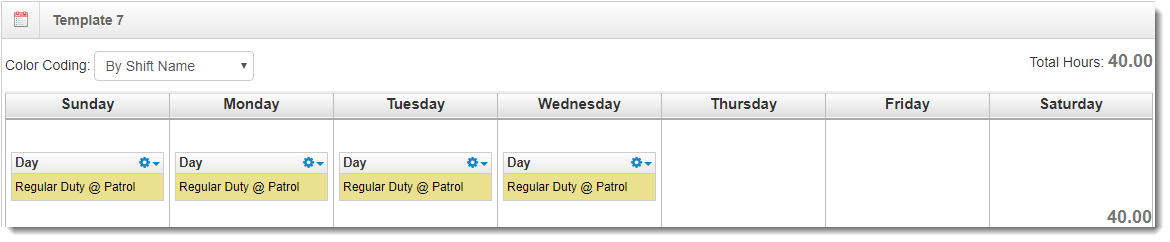

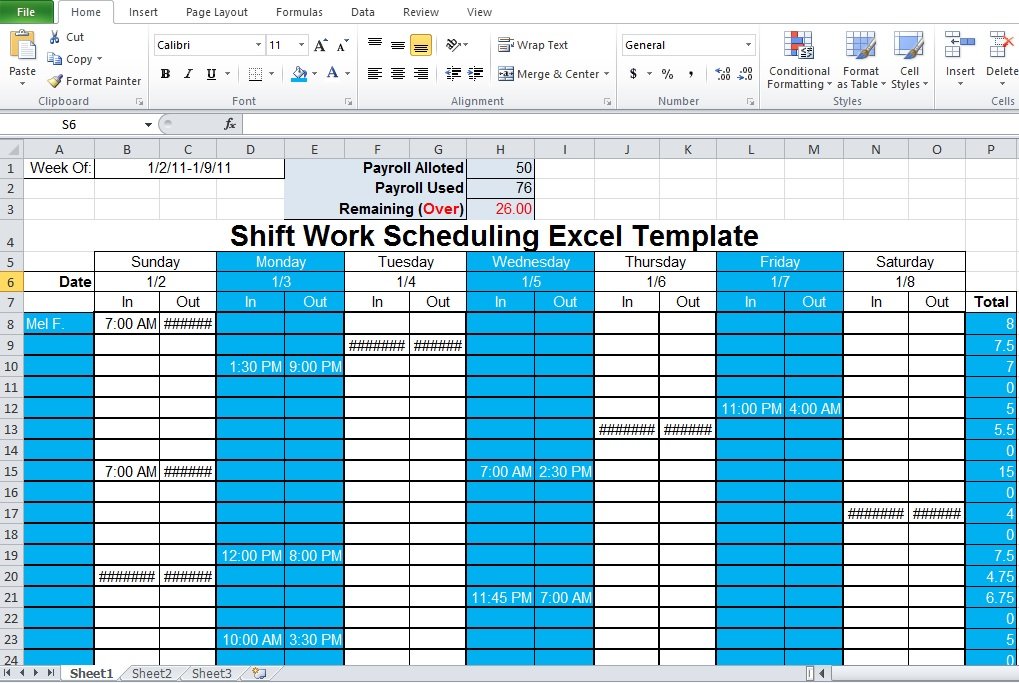

Creating a comprehensive shift schedule for 10-hour shifts can be complex. It requires careful consideration of employee availability, skill sets, and workload distribution. Organizations must develop a flexible and adaptable scheduling system to accommodate various shift patterns and employee preferences.

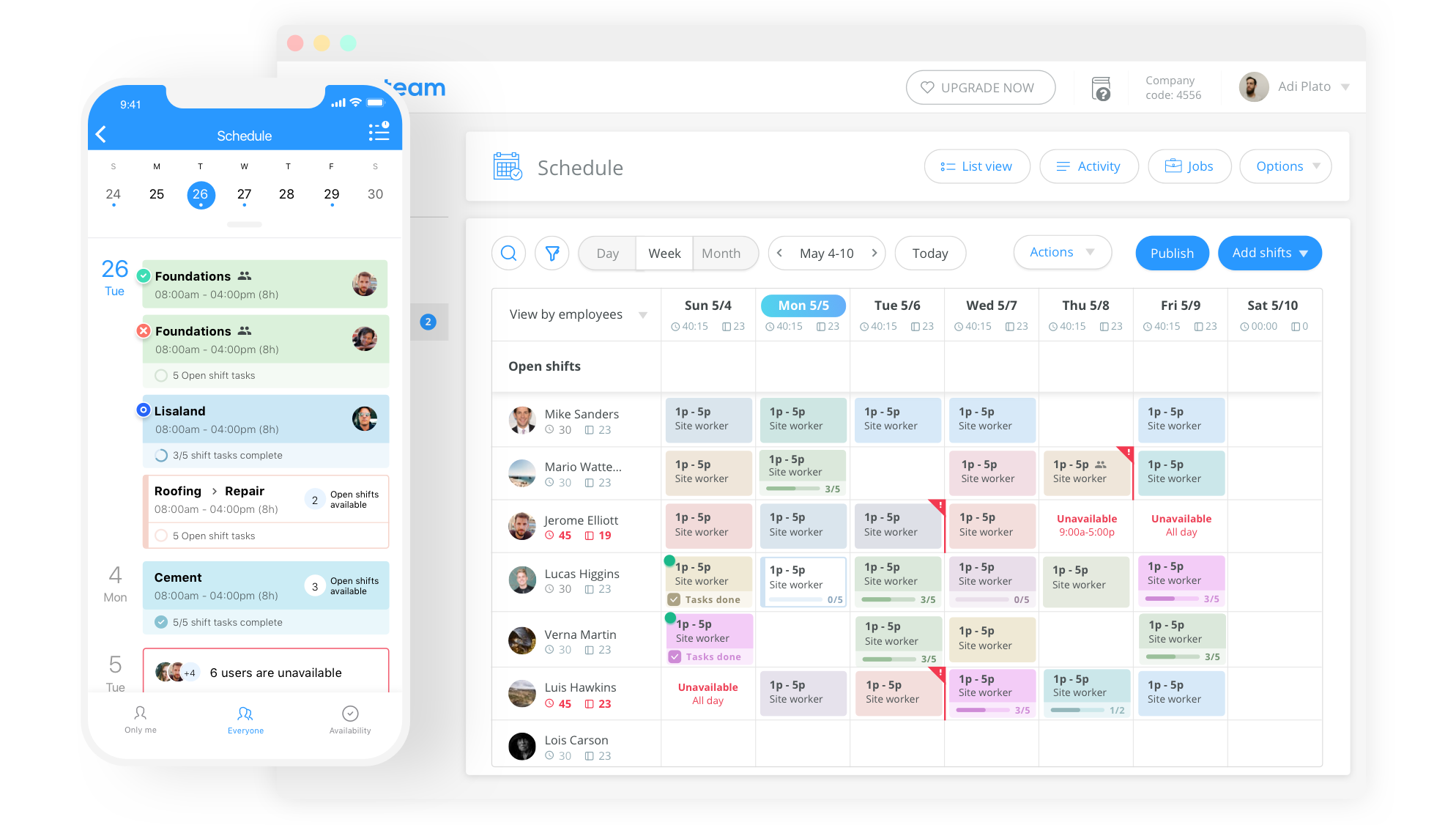

Advanced scheduling software can assist in optimizing 10-hour shift schedules. These tools can automate the process, taking into account employee availability, skill requirements, and workload distribution to create efficient and fair schedules.

Communication and Collaboration

Effective communication and collaboration are essential when implementing 10-hour shift schedules. Employees should be well-informed about the new shift patterns and the reasons behind the change. Clear communication ensures buy-in and helps address any concerns or questions they may have.

Encourage open dialogue and feedback sessions to address potential challenges and make necessary adjustments. Collaboration between management, supervisors, and employees is crucial for a successful transition to 10-hour shifts.

Strategies for Effective 10-Hour Shift Scheduling

To ensure the success of 10-hour shift scheduling, organizations should adopt strategic approaches that consider employee well-being, operational efficiency, and long-term sustainability.

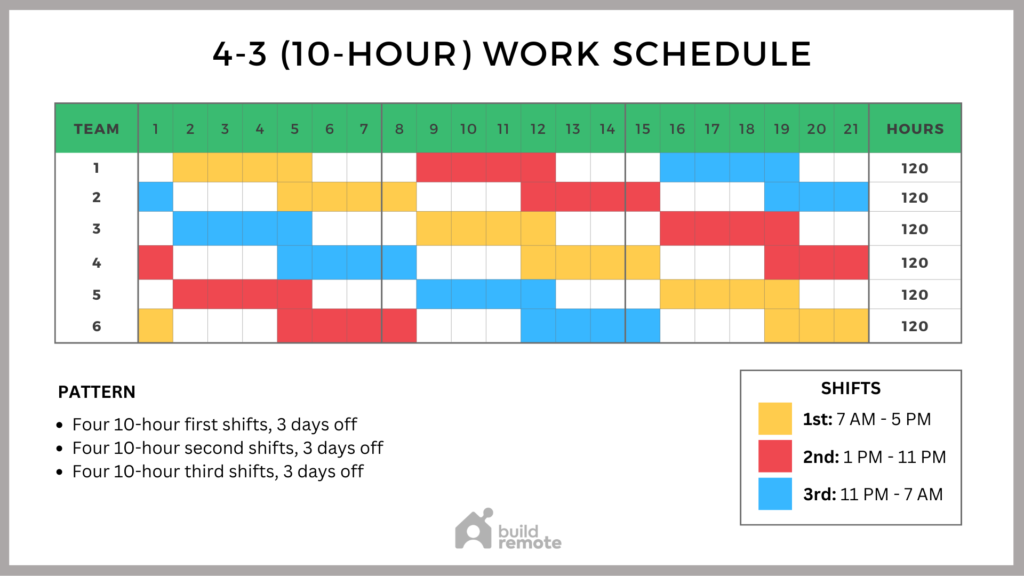

Flexibility and Rotating Shifts

Implementing flexible and rotating shift patterns can help manage fatigue and maintain employee engagement. Rotating shifts ensure that employees have a varied work schedule, reducing the monotony of long, continuous shifts. Flexibility allows employees to choose shifts that align with their personal preferences and availability.

Workload Distribution and Task Management

Effective workload distribution is crucial to prevent burnout and ensure a balanced work environment. Managers should carefully allocate tasks and responsibilities across shifts to maintain a consistent workflow. Regularly reviewing and adjusting task assignments can help prevent bottlenecks and ensure a fair distribution of work.

Rest and Recovery Strategies

Organizations should prioritize employee rest and recovery to maintain their well-being and productivity. This includes implementing mandatory break periods, encouraging healthy lifestyle choices, and providing access to wellness resources.

Additionally, organizations can offer flexible break options, allowing employees to take short breaks throughout their shift to recharge and stay focused. Providing comfortable break areas and promoting stress management techniques can further support employee recovery.

Continuous Feedback and Adjustment

10-hour shift scheduling is an ongoing process that requires continuous feedback and adjustment. Regularly collect feedback from employees to identify areas of improvement and make necessary changes. This iterative approach ensures that the scheduling system remains effective and aligns with the needs of the workforce.

Case Study: A Successful 10-Hour Shift Implementation

Let’s explore a real-world example of a manufacturing company that successfully implemented 10-hour shift scheduling. This case study highlights the key strategies and outcomes of their transition.

Company Overview

ABC Manufacturing, a leading automotive parts supplier, sought to enhance its operational efficiency and reduce costs. With a traditional 8-hour shift schedule, the company faced challenges in meeting production demands and maintaining a competitive edge.

Transition to 10-Hour Shifts

After thorough planning and consultation with employees, ABC Manufacturing implemented a 10-hour shift schedule. The company aimed to increase productivity, reduce overtime costs, and improve overall operational performance.

Key Strategies

- Employee Engagement: ABC Manufacturing involved employees in the decision-making process, ensuring their buy-in and support. Regular town hall meetings and open communication channels were established to address concerns and gather feedback.

- Flexible Shifts: The company introduced flexible shift patterns, allowing employees to choose their preferred shifts based on personal circumstances. This flexibility improved employee satisfaction and attendance.

- Workload Management: ABC Manufacturing implemented a task management system to ensure an equitable distribution of work. Regular reviews and adjustments were made to optimize workflow and prevent overburdening employees.

- Fatigue Management: The company prioritized employee well-being by implementing mandatory break periods and providing access to ergonomic workstations. Additionally, they offered wellness programs and encouraged healthy lifestyle choices.

Results and Outcomes

The transition to 10-hour shifts at ABC Manufacturing yielded positive results. The company experienced a significant increase in production output, with a 30% reduction in overtime costs. Employee satisfaction and retention rates improved, and the flexible shift patterns enhanced work-life balance.

By implementing effective fatigue management strategies and maintaining open communication, ABC Manufacturing successfully managed the challenges associated with extended work hours. The company continues to monitor and adjust its shift scheduling practices to ensure long-term sustainability and employee well-being.

Conclusion

10-hour shift scheduling offers a viable solution for organizations aiming to maximize productivity and operational efficiency. By carefully considering employee well-being, implementing flexible schedules, and prioritizing effective workload management, organizations can successfully adopt this scheduling approach.

Through strategic planning, continuous feedback, and a focus on employee engagement, organizations can unlock the full potential of 10-hour shifts, driving success and long-term sustainability. Embrace the benefits of extended work hours while ensuring a healthy and productive workforce.

How do I determine the optimal shift pattern for my organization’s 10-hour schedule?

+Determining the optimal shift pattern requires a comprehensive analysis of your organization’s unique needs and constraints. Consider factors such as production demands, employee availability, skill sets, and historical data. Collaborate with employees and conduct a trial period to gather feedback and refine the shift pattern.

What are some strategies to prevent employee burnout in 10-hour shift schedules?

+To prevent employee burnout, prioritize fatigue management and employee well-being. Implement mandatory break periods, provide access to ergonomic workstations, and encourage healthy lifestyle choices. Offer flexible break options and promote stress management techniques. Regularly monitor employee satisfaction and adjust schedules as needed.

How can I ensure a smooth transition to 10-hour shift scheduling?

+A smooth transition requires careful planning and open communication. Involve employees in the decision-making process, provide clear information about the new schedule, and address their concerns. Offer training and support to adapt to the extended work hours. Gradually implement the new schedule and be open to feedback for continuous improvement.