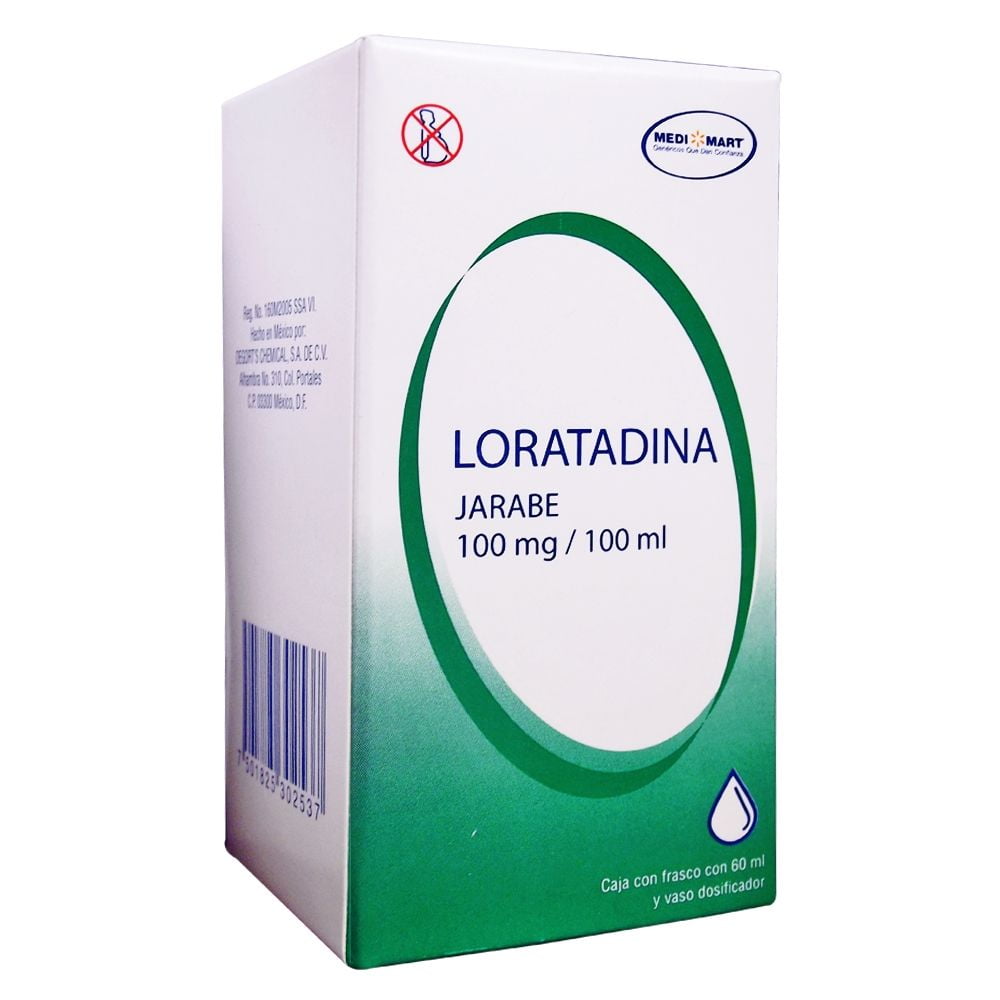

The 100 mg 100 ml Challenge: 3 Tips

In the realm of oral drug administration, the 100 mg/100 ml challenge is a well-known hurdle in pharmaceutical development. It refers to the process of formulating a stable and effective solution containing 100 milligrams of an active pharmaceutical ingredient (API) in 100 milliliters of solvent. This challenge is particularly significant in the context of oral liquid medications, which offer advantages such as ease of administration, rapid onset of action, and precise dosage control, especially for pediatric and geriatric patients.

Understanding the 100 mg/100 ml Challenge

The 100 mg/100 ml challenge is a critical aspect of oral drug formulation, especially for liquid medications. This challenge arises due to the solubility limitations of many active pharmaceutical ingredients (APIs) in aqueous solutions. To meet this challenge, formulators must employ innovative strategies to enhance the solubility and stability of the API while ensuring the overall quality and safety of the final product.

The solubility of an API in a given solvent is a key factor in determining the feasibility of the 100 mg/100 ml formulation. Insufficient solubility can lead to precipitation of the API, compromising the stability and efficacy of the medication. Therefore, a comprehensive understanding of the API's physicochemical properties, including its solubility profile, is essential for successful formulation.

Factors Influencing Solubility

Several factors can influence the solubility of an API in a solvent. These include the pH of the solution, the presence of excipients (inactive substances added to the formulation), temperature, and the API’s own chemical structure. For instance, the pH of the solution can significantly impact the solubility of an API, as many APIs exhibit pH-dependent solubility behavior.

Excipients play a crucial role in enhancing the solubility and stability of APIs. Surfactants, for example, can reduce the surface tension between the API and the solvent, improving solubility. Similarly, co-solvents can be added to the formulation to increase the solubility of the API by altering the solvent's polarity or hydrogen bonding capacity.

| Excipient Type | Function |

|---|---|

| Surfactants | Reduce surface tension, enhancing solubility |

| Co-Solvents | Increase solvent polarity, improving API solubility |

| pH Modifiers | Adjust pH to optimize API solubility |

| Stabilizers | Prevent API degradation, ensuring stability |

Overcoming the Challenge: Strategies and Tips

Overcoming the 100 mg/100 ml challenge requires a systematic approach and a deep understanding of pharmaceutical formulation science. Here are three key strategies and tips to successfully navigate this challenge:

1. Solubility Enhancement Techniques

To improve the solubility of APIs, formulators can employ various techniques, such as salt formation, complexation, and the use of co-solvents. Salt formation involves converting the API into a more soluble salt form, often by reacting it with a suitable acid or base. This strategy is particularly effective for basic or acidic APIs.

Complexation, on the other hand, involves forming a complex between the API and a suitable ligand, enhancing its solubility. This technique is often used for APIs with limited solubility due to their crystalline structure.

Co-solvents can also be used to increase the solubility of APIs. By adding a second solvent to the formulation, the overall solvent system can be tailored to enhance the solubility of the API. However, it's crucial to ensure that the co-solvent is pharmaceutically acceptable and does not adversely affect the stability or safety of the final product.

2. Stability and Compatibility Considerations

In addition to solubility, the stability and compatibility of the API with other formulation components must be carefully considered. APIs can undergo various degradation pathways, including hydrolysis, oxidation, and photodegradation. Formulators must choose excipients and packaging materials that minimize these degradation processes.

For instance, antioxidants can be added to the formulation to prevent oxidation of the API. Similarly, light-sensitive APIs may require packaging that provides protection against light, such as amber glass bottles or opaque containers.

Compatibility studies are also crucial to ensure that the API does not interact adversely with other formulation components. These studies involve assessing the physical, chemical, and biological interactions between the API and excipients under various conditions, such as different pH levels or temperatures.

3. Formulation Optimization and Quality Control

Once a stable and soluble formulation has been achieved, it’s essential to optimize the formulation to ensure its quality and performance. This involves fine-tuning the concentration of excipients, adjusting the pH, and optimizing the manufacturing process to ensure consistent product quality.

Quality control is a critical aspect of the formulation process. It involves rigorous testing to ensure that the final product meets all regulatory and quality standards. This includes assays to determine the API content, stability studies to assess shelf life, and tests to ensure the product's safety and efficacy.

The Impact and Applications

Successfully overcoming the 100 mg/100 ml challenge has significant implications for pharmaceutical development and patient care. It enables the formulation of stable and effective liquid medications, offering a more convenient and precise dosage form, particularly for patients who may have difficulty swallowing solid dosage forms.

Moreover, the ability to formulate liquid medications with high API concentrations allows for smaller volumes to be administered, improving patient compliance and reducing the risk of medication errors. This is especially beneficial for pediatric patients, where precise and accurate dosing is critical.

The 100 mg/100 ml challenge is also relevant in the context of personalized medicine. With the advent of precision medicine, there is a growing need for tailored drug formulations to meet the unique needs of individual patients. The ability to formulate liquid medications with high API concentrations allows for the development of customized treatments, ensuring optimal therapeutic outcomes.

Conclusion

The 100 mg/100 ml challenge is a complex but surmountable hurdle in pharmaceutical formulation. By understanding the factors influencing solubility, employing innovative strategies, and conducting thorough stability and compatibility assessments, formulators can successfully navigate this challenge. The resulting liquid medications offer numerous advantages, enhancing patient compliance, convenience, and precision in dosing.

FAQ

What is the significance of the 100 mg/100 ml challenge in pharmaceutical formulation?

+

The 100 mg/100 ml challenge is significant because it represents a solubility hurdle that many active pharmaceutical ingredients (APIs) face when formulating oral liquid medications. Meeting this challenge is crucial for ensuring the stability, efficacy, and quality of the final product.

What are some common solubility enhancement techniques used in pharmaceutical formulation?

+

Common solubility enhancement techniques include salt formation, complexation, and the use of co-solvents. Salt formation involves converting the API into a more soluble salt form, complexation involves forming a complex between the API and a ligand, and co-solvents can be added to increase the solubility of the API by altering the solvent system.

How do formulators ensure the stability and compatibility of APIs in liquid formulations?

+

Formulators ensure stability and compatibility by carefully selecting excipients and packaging materials that minimize degradation pathways. This includes adding antioxidants to prevent oxidation, choosing light-protective packaging for light-sensitive APIs, and conducting compatibility studies to assess interactions between the API and other formulation components.